Radial Drilling Machine: Diagram, Parts, Working Principle

- Home

- Radial Drilling Machine: Diagram, Parts, Working Principle

Radial Drilling Machine: Diagram, Parts, Working Principle

Welcome to your Radial Drilling Machine Guide - 2021!

Today, we are going to talk about the biggest and the heaviest drill machine of all time. A gigantic drill machine that is three times heavier than the world’s largest gorilla. We call it The Radial Drilling Machine.

In this post, I'm going to tell you 4 interesting things about the radial drill:

- What is Radial Drill Machine and why so many companies are using it as their everyday drilling tool?

- 7 Fundamental Parts of Radial Drilling Machine

- Working Principle of Radial Drilling Machine

- The Basic Construction of a Radial Drill Machine Explained in Plain English

What Is Radial Drill Machine?

Let's start with a definition, Radial Drilling Machine is a machine tool, primarily used for making round holes in large-size workpieces. Now, what do I mean by large-size? Let me give you an example.

Did you see that JCB bucket?

That's what we call a large-size workpiece. A part that has more than 15mm thickness and is almost impossible to lift by any normal human being. When you want to drill a 40 to 50mm diameter hole in that massive part, an ordinary drill machine is not a clever option. You have to use a heavy-duty Drill Machine, such as Radial Drilling Machine.

Why Is Radial Drilling Machine Important?

You see, JCB bucket manufacturers are not the only ones who deal with large-size parts. There are countless other manufacturers such as crane manufacturers, tractor manufacturers, truck manufactures, lathe machine manufacturers, and many more.

They all deal with large-size parts. And when it comes to making large diameter holes in these parts Radial Drilling Machine is the handiest tool out there in the machining industry. No wonder why they love using Radial Drill as their primary drilling machine.

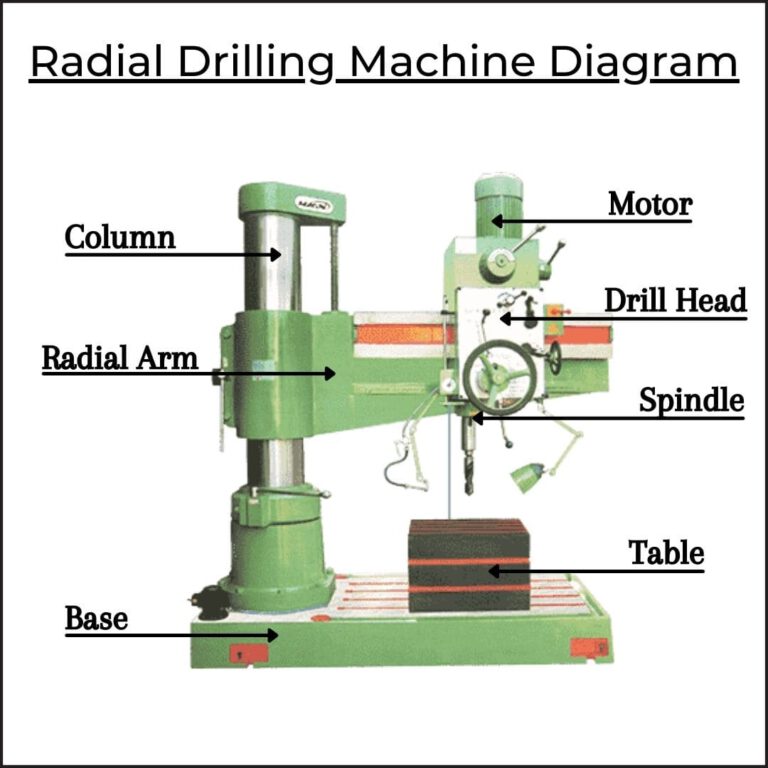

Radial Drilling Machine Diagram

You and I have now completed the basic introduction to radial drill machines.

Now is the time I let you know the most essential parts of it. To make it easy to understand, I have put a diagram of the radial drilling machine for you. I suggest you scan it from top to bottom and carefully understand which parts are called what and how does it look.

Those seven parts are the crucial elements of any radial drill machine. If you remove any of the listed parts, then the machine will be of no use. Here is a brief introduction to each one of them. So, you can get the idea of why they are so important.

Radial Drilling Machine Parts:

Here are the 7 fundamental parts of a radial drilling machine:

- Base

- Column

- Radial Arm

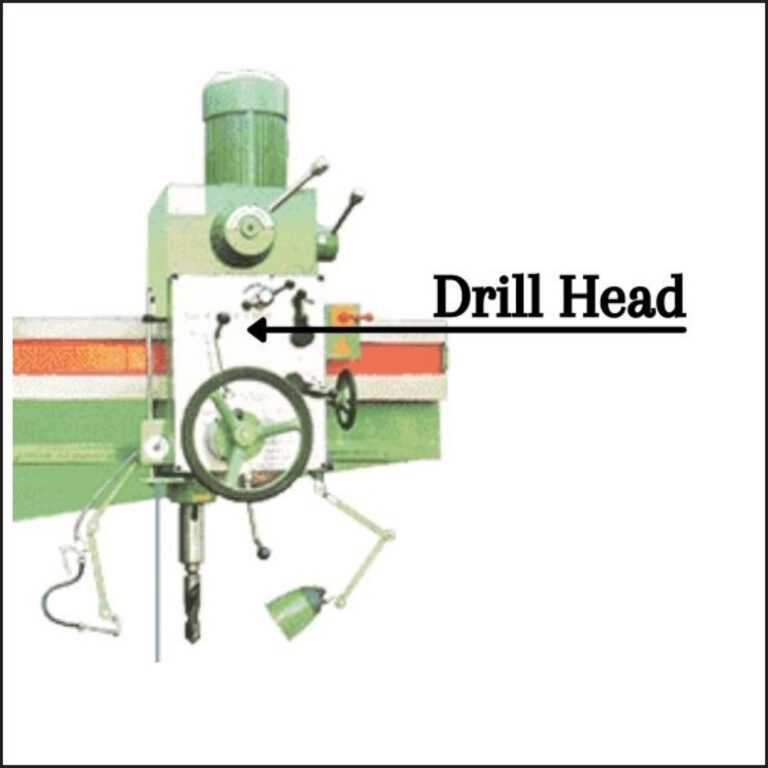

- Drill Head

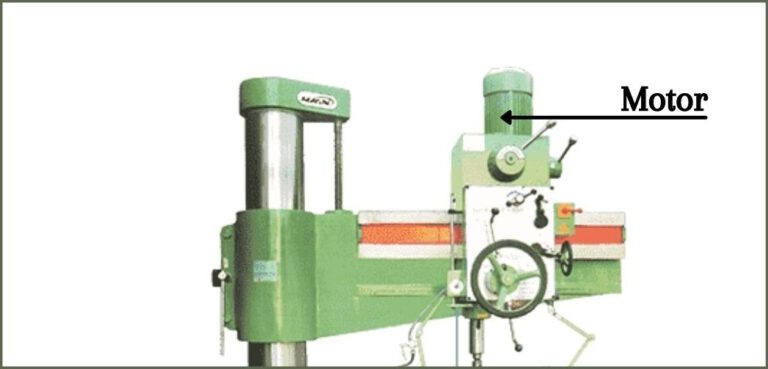

- Motor

- Spindle

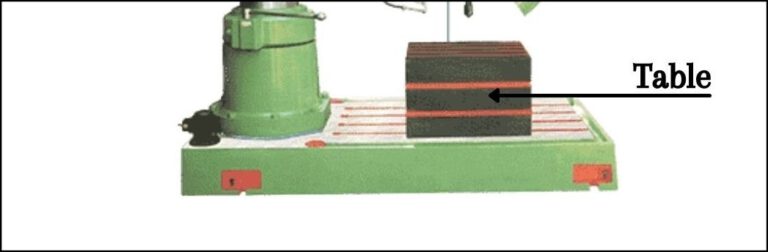

- Table

Now let’s discuss each part in brief.

1) Base

The base is the most important part of the machine. Usually, it is made of cast iron. The reason behind this is that when you use the radial drill for machining, there will be a lot of vibration in it. And because of this vibration, the machine parts could break.

In this situation, a base made of cast iron is very helpful. Because cast iron has a remarkable ability to absorb the vibration produced by the machine parts. But that is not the main function of the base. The main function of the base is to provide support to the assembly mounted on it.

Another thing you should know about the base is that most radial drill machine manufacturers make t-slot on the surface of the base so that you can fit worktable or other clamping devices easily.

2) Column

The column is a vertical pillar that is mounted on the rear side of the base. The main function of the column is to support and hold the radial arm assembly. Just like the base, it is also made from cast iron.

But before mounting the column on the base, the manufacturer of the radial drill has to make the column surface super smooth. There is a good reason behind it, You see, the radial arm that is mounted on the column is designed in such a way that it can slide easily up and down on the surface of the pillar. If the surface finish is not good, there will be a lot of friction between the two parts while moving the arm up or down.

3) Radial Arm

The radial arm is the coolest part of all. Because it has so many unique movements that make the radial drill machine different from any other drill machine. In fact, a radial arm is the only reason why the machine is called a radial drill.

Here is the list of movements of the arm along with benefits:

- You can rotate the arm 360 degrees around the column. This feature is very beneficial when you want to make a hole in a large-size part that you cannot place on the worktable.

- You can drill a part (very easily) without placing it on the table, simply by moving the arm on either side.

- You can slide the drill head horizontally from left to right. It enables you to drill multiple holes in a single setup. You don't need to relocate the workpiece, just slide the drill bit to a desirable place and you are ready to go.

4) Drill Head

Drill Head is the driving force behind the radial drill. It is mounted on the radial arm. It contains many important elements such as gearbox, motor, spindle, depth gauge, control panel, and many more.

By using the control panel, you can change the speed of the spindle, and with the use of a depth gauge, you can set the depth of the drill bit. You can also switch between auto or manual feed mode by using a spindle wheel.

5) Motor

The motor is mounted just above the drill head. Its main job is to provide rotary drive to the spindle. When you are buying a new radial drilling machine, you should check for the motor power. The more drill capacity you want the more powerful motor you will need.

6) Spindle

A spindle is a rotating shaft with a fixture that holds your cutting tool. The main function of the spindle is to support your tool and provide a rotary drive so that it can easily make a hole in your workpiece without breaking or falling.

7) Table

Table, as it sounds, is a worktable. It provides you the facility to hold the workpiece during the drilling operation. Just like the base, the table also has a few t-slots on it so that you can fit clamping devices to hold your job.

Usually, the table comes in a round or rectangle shape. (most users do prefer rectangle table). But you can also purchase a modified table so that you can drill a cross hole in your workpiece if you want.

Working Principle of Radial Drilling Machine:

Radial Drill Machine Mechanism

When the operator turns on the motor, it starts spinning. With the help of a gear or pulley drive, the power of the motor is transmitted to the spindle.

There is a medium-size control wheel on the right-hand side of the drill head. By using this wheel, the operator starts applying a slow-pressor on the job which is pre-located below the drill bit. Due to the pressure, the excess material starts coming out of the workpiece and a hole starts to form inside the job.

Radial Drill Machine Construction:

When it comes to the construction of the radial drilling machine, the base is the most important part because it weighs the rest of the machine parts. At the rear end of the base, the column is placed. On the other hand, t-slots are made on the front-end surface. Nowadays, a small coolant tank is also made inside the base.

If we talk about the column, mainly two parts are attached to it. Radial arm and elevating screw. With the help of elevating screw-up-down movement is given to the arm. A sliding drill head is mounted on the arm. On the head, there various small to medium size parts are fitted. In which motor, spindle, depth gauge, and control panel are chief.

Two wheels are also fitted on the drill head, one is to feed the spindle, and the other is for the head’s sliding movement over the arm. At last, there are numerous levers fitted to lock or unlock radial arm and spindle movements.

Types of Radial Drill Machine

Here is the list of the most popular types of radial drill machines:

- Plain Radial Drilling Machine

- Semi-Universal Radial Drilling Machine

- Universal Radial Drilling Machine

- All Geared Radial Drilling Machine

- Double Column Radial Drilling Machine

- Automatic Radial Drilling Machine

- CNC Radial Drilling Machine

- Heavy Duty Radial Drilling Machine

- Small Radial Drilling Machine

So... What Do You Think?

Now I want to hear from you. What do you think of this post?

Or maybe I missed some details you want to know. Either way, let me know by leaving a comment below.

Blogger

Diigo

Evernote

FlipBoard

Gmail

Google Bookmark

LinkedIn

LiveJournal

MySpace

Pinterest

Pocket

Reddit

Skype

Telegram

Tumblr

Yahoo Mail

GoQR.me

Wordpress