Best Radial Drilling Machine Manufacturer in India

- Home

- Best Radial Drilling Machine Manufacturer in India

Best Radial Drilling Machine Manufacturer in India

Drill Press

A standard Radial drilling machine tool for drilling is a drill press [Wikipedia]. There are several types of exercise presses, in which the most basic direct drill is, Figure 1. Direct drill stays on the floor and drill head with a workpiece, spindle operated for a drill bit, and a base for support, and a table to hold the column. Similar drill press, but small, benches are the exercise, which is mounted on a table or bench in place of the floor.

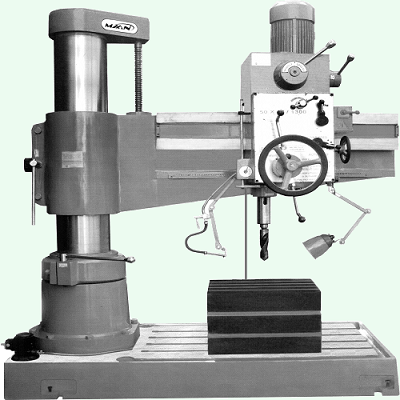

All Geared Radial Drilling Machine

Radial Exercise, Figure 2, is a huge exercise press to make most of the holes cut. He has a radial hand with which the drilling head is moved and clamped. Therefore, the head can be positioned on hand in places with considerable distance from the column for most operations. The radial box can be swiveled on the column to either exercise on both parts of the worktable.

Radial Drilling Machine

The Radial drilling machine is mainly used for specific depths of the various holes of the objects and the surface of the object. In addition, the drilling machine can do other tasks such as tapping, rimming, counter-sink, spot facing, countersinking, etc. It is commonly known as a drill press and has the ability to use very small pores and very large pores. The drilling machine is considered a very early and most essential machine tool. Numerous varieties of drilling machines are now available in production and are readily available in the market; All drilling machines, including radial drilling machines, actually operate the same basic drilling work.

However, there are certain specific operations that can be done very accurately and accurately through specific drilling machines. It is used in many manufacturing processes and especially in the construction industry. Today's radial drilling machines are provided in different types and sizes of drill heads and base plates, including all the gear radial drilling machines. They have been designed to complete numerous engineering tasks related to operational and specific requirements. Spindalani cooling systems and power feed radial drilling machines have common characteristics.

Best Radial Drilling Machine Manufacturer in India

There are a lot of Radial Drilling Machine Manufacturer Companies in India. here a comparison of some of the company's Model vise Specifications that helps you to know which one is the best? Our main aim is to serve the domestic as well as an international market by providing top quality machines in various specifications.

Maan Technoplus Radial Drilling Machines

Features:

✔ Main Spindle is made of "EN8" material and hardness

✔ MT-bore internally grinded

✔ Accuracy and run out of 0.01 to 0.03 in the main spindle shaft

✔ Provided 4-8 speeds by accurate balancing

✔ Spindle sleeve-grinded

✔ Work light[As per requirement]

✔ Full-size work table with accurate right-angled.[390X300][Surface Grinding is available as per your required]

✔ Tapper Roller facility for better sliding of the drill head and arm guide

✔ Coolant system [As per requirement]

✔ Speeds can easily change

✔ Nitride Hardened "Ram"

✔ All gears are made of alloy steel[Gear Material] and Heat treatment [50 to 60 HRC] hardened & Lapped running in an oil bath fitted with splined shafts

✔ Ram is accurately ground and Honing process is done in the boring body containing "Ram"

✔ All the gears assemble in the machine are perfectly sized according to a requirement

All Bearing [SKF/NSK[Japan]/NBC Bearing]

✔ All Electrical parts are of good quality.[Company: L&T]

✔ Pinion and worm is ground as per the sizes required

✔ Column Design is the heavy thickness and ground as per the sizes required [column size:180mm]

✔ Spindle reverse and tapping control[As per your required]

✔ Especially spring-type balanced spindle travel

✔ Manual And Auto feed options

✔ The Auto feed mechanism is designed in such a manner that if in case the machine gets overloaded or the drill bit may get locked during operation the machine will automatically start slipping that will prevent any accident or any kind of damages

✔ Drilling last capacity: 40mm

✔ Heavy Duty structures

✔ Strongly ribbed and a thick-walled base plate having a built-in coolant tank.

Generously Proportional & Well adequately ribbed base plates and column & arm for maximum rigidity and minimum deflection

✔ This machine may be capable of drilling & milling & tapping & honing & counter-boring & spot facing & Reaming & boring and other similar utilities.

The arm guide surface is a precision scraping process

✔ Wooden case available on demand

Batliboi Radial Drilling Machines

Features:

✔ Arm, column & base rigidly built with reinforcement ribs to reduce distortion and give long life

✔ Heavy-duty - 75 mm drilling in solid steel

✔ Pre-selection of spindle speeds

✔ Electro-hydraulic clamping for drill head and arm swivel

✔ Special spindle bearing arrangement for rough boring

✔ Quill and spindle assembly balanced by the guided counterweight

✔ Automatic lubrication of drill head and arm

✔ Automatic clamping / de clamping of an arm for up and down movement

✔ A wide range of speeds and feeds

✔ Automatic disengagement of power feed at required depth of drilling

HMT Radial Drilling Machines

Features:

✔ Massive and rigid construction.

✔ Ergonomically grouped controls for operating convenience.

✔ Light centering of a spindle.

✔ Precise depth release.

✔ Electrohydraulic clamping provided for drill head, arm & sleeve.

✔ Shock-free engagement of taps through clutch and spindle reverse for withdrawals.

✔ A machine with a drilling capacity of 80 mm / 100 mm also available.

Siddhapura Radial Drilling Machines

Features:

✔ DRILLING (M.S)-50MM

✔ SPINDLE TAPPER-MY-5

✔ POWER SUPPLY-3PH,415V,50HZ

✔ DISTANCE FROM COLUMN TO SPINDLE MAX/MIN.-1210/400

✔ OVERALL DIMENSIONS(L X W X H)-1800 X 1000 X 2450

✔ APPROXIMATE WEIGHT-2500KG

✔ BOX TABLE AREA(LXWXH)-600 X 500 X 500

Components of Radial Drilling Machine

Columns - Part of the radial hand drill press, which has a radial arm that can be moved according to its length

Arm Rise - Arrange the vertical height of the radial bounds with the column

On / Off Button - is the switch that activates the drill press and disables it

Arm clamp - hand in column and place

Table - The place where Workspace is given and it works

Base - Radial hand drill is a press piece that supports columns and tables

Spindle - Drill is a rotating part of the press that holds the cutting tool used in holding the cutting tool

Drill Head - The part of the drill press that penetrates through the material or workpiece and drills through a special hole size

Radial Arm - Drill Head holds an assembly and supports it and is moved to its length level

There are many benefits to using a radial hand drill press. One of these advantages is the amount of the area that it can cover, which is based only on the length of the hand. Another advantage is the significant size of the work that it can handle because the hand actually allows Kearney and Derrick to place a workspace on the table from the work area. Finally, less effort is required during the drilling process because all of the functions required for specific functions to complete hand assembly enzymes are to be done.

Blogger

Diigo

Evernote

FlipBoard

Gmail

Google Bookmark

LinkedIn

LiveJournal

MySpace

Pinterest

Pocket

Reddit

Skype

Telegram

Tumblr

Yahoo Mail

GoQR.me

Wordpress