How It's Made? Drill bits. Raw Material and Manufacturing Process used in Industries.

- Home

- How It's Made? Drill bits. Raw Material and Manufacturing Process used in Industries.

How It's Made? Drill bits. Raw Material and Manufacturing Process used in Industries.

Drill bits

The tools used to remove the material to make a hole are nearly chopped almost always rounded cross-section. Bits come in many sizes and shapes and can make different types of pores in many different materials. To make holes, drill bits are usually associated with a drill, which reduces it by a workpiece, especially by rotation. This exercise will understand the upper part of the beat, which is known as a stem in Chak.

Spade, lip, and spur (brad point), masonry bit, and twist drill bits

Drill bit, mounted on a bench press drilling machine.

A set of masonry drill bits

Drill bits come in standard sizes, which are studied drill bit in size. Metric and royalty-sized drill bits with essential screw tape size Extensive drill bit and tape-shaped chart list There are special drill bits that can make a hole in the non-circular cross-section.

In drilling machines, drill bit or bit is used for the drilling machines, for a brief reference to use a drilling machine or radial drill machine, And the drill always refers to the drilling machine.

Characteristics

There are many characteristics in drill bit geometry:

- Spiral (or twist rate) in the drill bit controls the rate of chip removal. Quick spiral (high twist rate or "compact flute") drill is used in high feed rate applications at low spindle speeds, where a large number of chips need to be removed. Low spiral (low twist rate or "elongated flute") drill bits are used to cut applications, where high cutting speed is traditionally used, and where the material is bitten on a bit or else the hole, such as aluminum or copper.

- Point Angles, or nodes formed at the top of the beet, are determined by the content, which will be a functional bit. Strict content needs a big point angle, and soft material needs a more sharp angle. The right point angle for physical effects, chatter, hole shape, and wear rigidity.

- The lip angle determines the amount of support the cutting edge provides. The lip angle can cut as much as a little point pressure by a smaller point as aggressive. In both situations, there may be instrument binding, wear, and final destructive failure. The correct amount of lip clearance is determined by point angle. The web surface area is presented at any point is very sharp point corners, which requires an aggressive lip angle, where the small surface area supporting the edge of the cloth is sensitive to small changes in the corner of the lips.

- The length of the bit determines how the hole can immerse in the chin, and as a result of the hole's hole and the accuracy of the accuracy also determine. When bits can be exercised deeper holes for a long time, they are more flexible, which means they may be wandering through holes in an improper place or intended axis. Twist drill bits are available in standard length, which is referred to as stub-length or screw-machine-length (short), very common job-length (middle), and diminished-length or long-series (long).

Most exercise bits for consumer use are straightforward thorns. For heavy-duty drilling in the industry, bits with taped shanks are sometimes used. Other types of suspicion include hex-shaped and various proprietary fast release systems.

The diameter-to-length ratio of a drill bit is usually between 1: 1 and 1:10. A lot of proportion is possible (eg, "aircraft-length" twist bits, press-oil gun drill bits, etc.), but the highest ratio, the technological challenge to produce better work.

The best geometry to use is based on the properties of the drill content. The following table lists the geometry recommended for some commonly drilled content.

Workpiece material | Point angle | Helix angle | Lip relief angle |

|---|---|---|---|

| Aluminum | 90 to 135 | 32 to 48 | 12 to 26 |

| Brass | 90 to 118 | 0 to 20 | 12 to 26 |

| Cast iron | 90 to 118 | 24 to 32 | 7 to 20 |

| Mild steel | 118 to 135 | 24 to 32 | 7 to 24 |

| Stainless steel | 118 to 135 | 24 to 32 | 7 to 24 |

| Plastics | 60 to 90 | 0 to 20 | 12 to 26 |

Drill Bits Materials

Depending on the required application, many different materials are used or used for drill bits. Many hard materials such as carbide are more brittle than steel, and are subject to more breaks, especially if the workplace is not kept at a very constant angle; Eg. When caught by hand.

Steels

- Soft Low-Carbon Steel Beats are cheap but do not hold the edge well and often do not require sharpness. They are used only for drilling wood; Working with hardwoods instead of software can reduce their lifespan.

- Beats made of high carbon steel are more durable compared to low carbon steel due to their rigid and tear-bearing properties. If they are hot (i.e., heat dissipation) they lose their temper, resulting in a soft cutting edge. These bits can be used on wood or metal.

- High-Speed Steel (HSS) equipment is the type of steel; HSS bits are more resistant to air than hard and high-carbon steel. It can be used to drill metal, hardwood and most other materials at higher cutting speeds than carbon-steel bits, and most often the carbon steals are replaced.

- Cobalt Steel Alloys have a variety of high-speed steel, which includes more Cobalt. They have very high temperatures and are used to make use of stainless steel and other hard materials. The main disadvantage of cobalt steels is that they are more brittle than standard HSS.

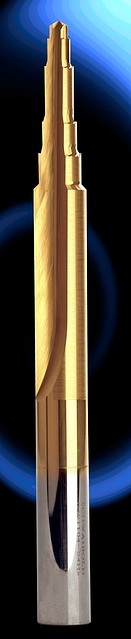

Titanium nitride coated drill bit

Others

- Tungsten carbide and other carbides are extremely difficult and can use virtually all of the material while holding the edge longer than other bits. This material is more expensive and brittle than stolen; As a result, they are mainly used for a small portion of fixed or refreshed hard materials on drill-bit tips, tips made of less hard metal. However, it is becoming more common in job shops to use solid carbide bits. Carbide tips are difficult to fit in very small size; In some industries, especially PCB manufacturing, where the diameter is less than 1 mm in diameter, solid carbide bits are used.

- Polycrystalline diamond (PCD) is one of the cheapest of all materials and so it is extremely resistant to wear. It is bound as a diamond particle layer, especially about 0.5 mm (0.020 in) thick, tinted-carbide support as a set. Tigestane-carbide "nib" is made to form small segments at the top of the instrument for making bits using the material to make a vein cutting edge or CCD. After carbon, the carbide shaft can be brushed; Then there may be grounds of complex geometry, which would otherwise be due to bras failure in smaller portions of "segments". PCD bits are typically used to drill covert aluminum alloys, carbon fiber reinforced plastics, and other abrasive materials for automotive, aerospace, and other industries, and machines are incredibly expensive to apply or replace bits worn in downtime applications. It should be noted that due to the reaction between the carbon and the iron in the metal, PCD is not used because of excessive wear.

Coatings

- Black oxide is a cheap black coating. A black oxide coating provides heat resistance and lubricity, as well as corrosion resistance. The coating enhances the life of high-speed steel bits.

- Titanium nitride (TiN) is a very hard ceramic material used for high-speed steel beats (usually twist bits), which extends the cutting life three or more times. Even after sharpness, the leading edge of the coating still provides improved cuttings and lifespan.

- Titanium aluminum nitride (TiAIN) is the same coating that can extend tool life five or more times.

- Titanium Carbon Nitride (TiCN) is another coating that is also superior to Tian.

- Diamond powder is used as a covert, usually for cut tile, stone, and other hard substances. Large amounts of heat arise from friction, and diamond-coated bits often cause damage to beet or workspace for water or cooling.

- Under the name of the Curtainsman brand, Zirconium nitride has been used as a drill-bit coating for some equipment.

Blogger

Diigo

Evernote

FlipBoard

Gmail

Google Bookmark

LinkedIn

LiveJournal

MySpace

Pinterest

Pocket

Reddit

Skype

Telegram

Tumblr

Yahoo Mail

GoQR.me

Wordpress